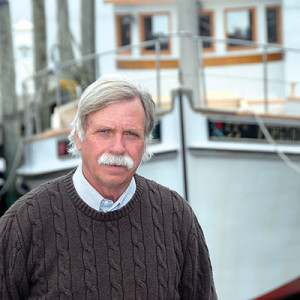

There are not too many oystermen on the Chesapeake Bay who can build their own boat, but Myles Cockrell of Little Wicomico Oyster Company of Heathsville, Va., is an exception.

Myles and his father, Andy own Cockrell’s Marine Railway, where Miles built the Capt. William, a 40’ x 16.5’ x 11” light/2’ loaded fiberglass oyster planter. The boat is named Capt. William after Myles’ three-year-old son.

The scow-style planter was launched on May 28, and Cockrell is currently using the new boat to plant shell on oyster grounds on Cockrell and Gougher creeks and off Haynie Point on the Great Wicomico River.

The Cockrells lease oyster grounds from the State of Virginia and plant about 3,000 bushels of shell to an acre to create a layer of clutch for oyster larva to attach to and grow. Capt. William carries between 700 and 800 bushels of shell in the aluminum hopper.

A front-end loader dumps shell into the hopper and a conveyor belt located under the hopper moves the shell forward. The shell travels to a “spinner” style spreader that extends out over the bow. The spreader broadcasts shell evenly over the oyster grounds, says Cockrell.

Not enough is always said about the importance of the mom-and-pop machine shops located up and down the waterways of the United States where commercial fishermen work.

Bert & Cliff’s Machine Shop at Wicomico Church, Va., built the aluminum hopper and spreader and installed a hydraulic power unit to run the conveyor belt and spreader. Bert & Cliff’s Machine Shop is an integral player in the seafood industry on Virginia’s Northern Neck where the Cockrells and others work the water.

Capt. William’s hull is made out of carbon honeycomb core sheets and coated with several layers of fiberglass. The stern is made of Coosa Composite high-density polyurethane foam boards and reinforced and coated with fiberglass.

The Capt. William is powered by two 300 h.p. Suzuki outboard engines that can push the boat 30.9 knots with the weight of the hopper on deck and topped off with 200 gallons of fuel. There are two fiberglass 100-gallon fuel tanks installed that were fabricated at the boatyard.

Dometic jack plates are attached to the two engine brackets. The jack plates raise and lower the outboard engines six inches straight up and down. An aluminum cage surrounds the engines to buffer the motors from when backing up near a dock.

Cockrell says he has started another oyster planter that he plans to use in even shallower grounds than he is working in now. That oyster planter will be 36’ x 12’ with a similar design to the Capt. William.