Maritime Fabrication in La Connor, Wash., has four older 32-foot Bristol Bay gillnetters in for modifications and in late March, was close to completing a new gillnet drum design for Bristol Bay that should get the attention of a lot of salmon fishermen.

The Lady Mindy was built in 1993 or 1994 by Rozema Boat Works, said Maritime Fabrication’s Isaac Oczkewicz, and when it leaves Maritime Fabrication on April 17, the Lady Mindy will go out with a new enclosed tophouse instead of the open flybridge it came in with. A helm station is part of the enclosed top house, along with a bunk “for more creature comfort,” said Oczkewicz.

The oldest of the four Bristol Bay boats in for renovations is the Stardust, built about 1979 at Alaska Marine Industries in Seattle. To gain additional vertical clearance in the engine room for its Volvo engine, the cabin floor was raised “about 14 or 15 inches,” said Oczkiewicz. That required cutting the cabin all the way around and raising the full cabin with windows and roof an equal amount.

The third gillnetter is the Jimmy O, built-in 2015 by Maritime Fabrication. The work involves fine-tuning and reconfiguring the hydraulics.

The Silver Bay, a Marco 32 built in San Diego in the mid-1980s, was being repowered. A Cat 3208 came out and a Cat C7.1 will be powering the Silver Bay in the 2023 Bristol Bay salmon season. The Silver Bay’s owner did the repowering, says Oczkewicz. “We weren’t involved except for some hydraulic work and welding in the fish hold.”

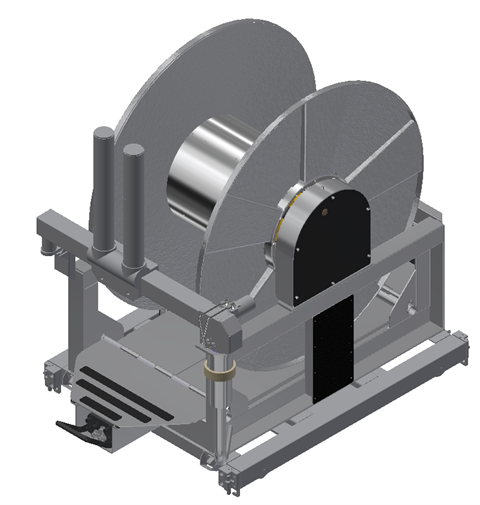

Probably at the top of the list on the deck machinery side of Maritime Fabrications, work is the new gillnet drum design. The driving force behind the design is that “some drums are not holding up well under the faster setting speeds some new jet boats are using,” said Oczkewicz. “That drum is direct drive going 15 to 20 knots, and the net’s flying out the back.”

Thus, the drum drive is spinning much faster than its hydraulic motor manufacturer recommends, thus, the net drum’s hydraulic motor may fail.

The fishermen’s solution to burning out the hydraulic motor has been to carry a spare hydraulic motor on the boat. Maritime Fabrication’s solution is basically to add a clutch to the system. That allows the drum to freewheel without spinning the hydraulic motor.

“It gives more control and better freewheeling,” says Oczkewicz. Instead of using a hydraulic motor brake, a disc brake is employed to slow down and stop the drum. Its “braking action is a much more positive way to stop the drum. We are trying to make a product that’s very robust and can function in the normal working conditions these guys are putting it in. We’ll be the only one with that option.”

The idea for the drum design emerged from discussions among Maritime Fabrication and others at the 2021 Pacific Marine Expo in Seattle. Not quite two years later, the new drum is in its final fabrication stages. This season there will be one boat fishing Bristol Bay with the new drum, then Maritime Fabrication will start taking orders for 2024.