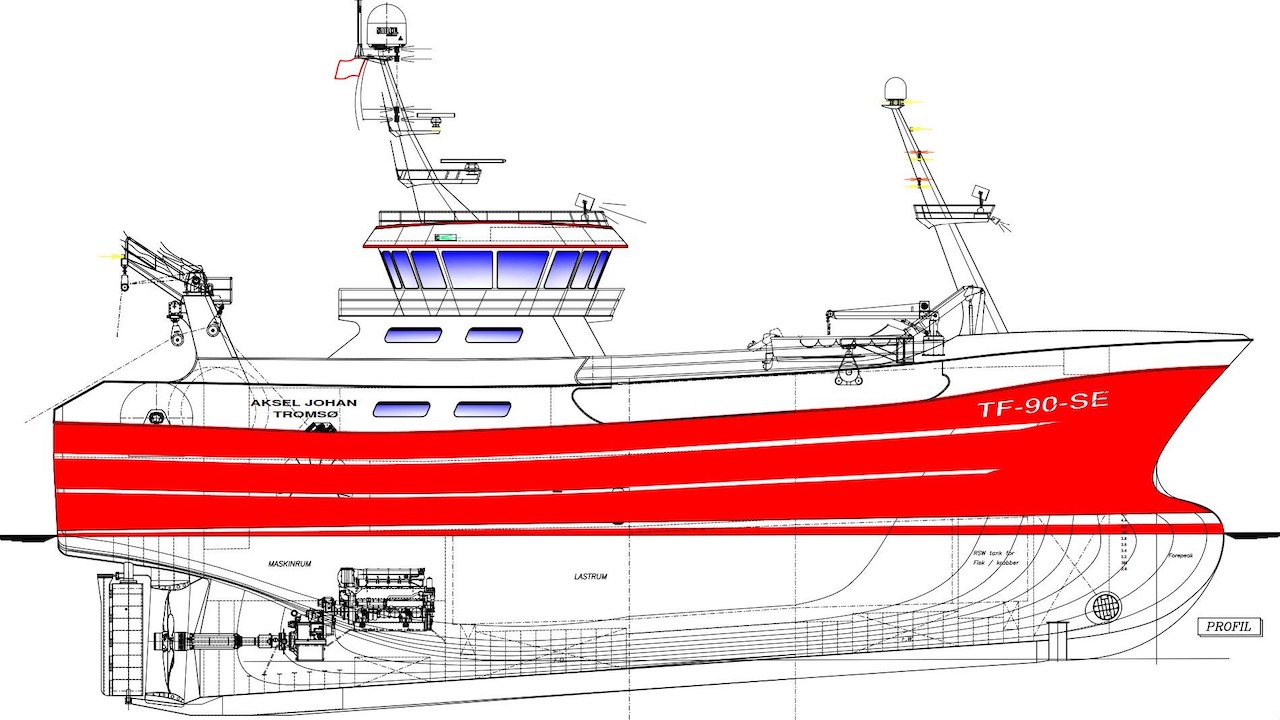

A new seiner and crabber, Aksel Johan, in Denmark, has made a serious splash in fishing technology and built by Vesrvaerftet ApS on the Danish West Coast, specializing in new builds for the fishing industry. Their customers are typically from Northern Europe, and they take pride in building vessels that are precisely what the customer wants.

Aksel Johan looks to be the most fuel-efficient fishing vessel afloat, according to Hook and Net Mag. Being the first fishing boat to use a thermoelectric system to utilize heat from the exhaust. The vessel’s propulsion is battery hybrid with load balancing on the engine and exhaust gas cleaning. Aksel Johan was built for Berg Fisk AS of Senjahopen, Norway. It was months behind its scheduled delivery from the Baltic yard due to the war in Ukraine causing a shortage of workers; saying construction was a challenge was an understatement with the delivery date being October 2023.

According to Berg Fisk’s director, Johan-Arild Hansen, the vessel performed flawlessly on its delivery trip from the yard. The vessel, which was over 130 feet in length, was lengthened by 26 feet from its original design to provide more carry capacity and more space for accommodations. Increasing the length also brought delays and made the final cost of the build almost $19 million in U.S. dollars.

Berg Fisk justified the investment due to reduced fuel costs and a grant from ENOVA, managing Norway's Climate and Energy Fund. F/V Aksel Johan has an exhaust boiler and a complete system to recover heat from the exhaust gases. This heats water, which is used to generate electricity. This technology has been used on land-based installations; however, according to the tech supplier Ulmatec, this is the first time this technology has been used on a fishing vessel.

Aksel Johan has already completed trials to ensure the system’s operations will perform adequately under operating conditions. Normal operations typically produce 25kWh; however, the thermoelectric system eliminates service costs. There is also a system for the on-board heating that uses cooling water from the engines. The vessel is expected to operate 300-320 days each year. Using the heat from the exhaust and the cooling water is expected to save up to more than 26,000 gallons of diesel annually.

The vessel has a 600-kWh Corvus battery, with the shaft generator producing electricity, optimizing the use of the main engine. The 1100 Kw Mitsubishi S6U produces 110 kW, with excess energy routed to the battery. These have the capacity to power propulsion for short periods of time, and the variable-speed shaft generator ensures optimal utilization of the main engine, regardless of the engine speed.

Two John Deere and Nogva Scania generators and a propulsion battery are included. These systems were tested during trials and provided a six-knot streaming speed. Aksel Johan can move within its port without running the main engine, keeping fuel consumption low.

To read more and see the design of Akel Johan, visit Hook and Net Mag.