In Bayou La Batre, Alabama, older boatbuilders pass on skills to the next generation.

When cotton was king in the South, wooden boats built in Maine carried the crop to the mills of England. Now that scallops and lobsters are the kings of New England and Mid-Atlantic fisheries, many of the boats for these fisheries are being built of steel in the South.

When it comes to steel boat building in the south, Bayou La Batre, Alabama, is ground zero. Fed by Bishop Manor and Hammer Creeks, the waters of the bayou are lined with fish houses and boat yards.

Among them, Williams Fabrication sits at the end of Seafood House Road, six acres of steel boats in various stages of construction. In a building next to a trailer that house the company office, Lane Williams is working on getting a forklift going. “It’s the holidays, and here we are,” he says.

Lane oversaw the building of the New Bedford scalloper Viking Power for Lars Vinjerud II in 2019 (NF December 2019), and has two more boats for Vinjerud rising alongside the bayou. The Viking Power, with its version of an X-type bow, was a unique project for the yard. “Daddy designed the Viking Power,” he says. “He’s not a naval architect, but he drew it up and took it to an architect, and they did the calculations. We didn’t want to build a submarine.”

The boat has been fishing for three years now, and Williams reports that it is working well. “Nobody’s ordered another one,” he says. “But it’s doing okay. We just launched another one for Lars, the American Viking, but that one had a regular bow.”

Vinjerud likes to try new things, and so does the team at Williams, particularly Lane’s father, Dale. “Daddy grew up in Fowl River, and he lived right across from Ellis Zirlott’s wooden boat yard. “He didn’t do much in high school, but when he was 18 he went to school at Ingalls to learn ship fitting, and he decided he was going to be the best. He credits what he knows to the old-timers who taught him.”

Although officially retired, Lane’s father, Dale comes down to the yard to see what needs to be done. Dale Williams founded the company in 1988. “In the beginning, I was mostly doing contract work, drawing boats,” he says. “I can’t tell you how many boats I’ve drawn, hundreds. I have files and files. I started drawing boats when I was a little boy growing up across from a boatyard. I’d get some paper and start drawing them.”

Dale Williams’s formal training consisted of an apprenticeship at Ingalls Shipbuilding in Pascagoula, Miss. “I’m a Christian,” he says. “I believe God puts the people in your path that you are meant to learn from — the good ones and the bad ones. They put me in the mold loft at Ingalls.” According to Dale, the term mold comes from modeling, and the first thing he saw when he got there was a half-model covered with lines for the offsets.

“I didn’t know exactly what it was at the time, but a guy there took me under his wing and gave me a book on lofting. I started to look through and thought, ‘Oh, I’m gonna learn this!” Dale’s enthusiasm for the trade attracted the attention of other older ship fitters, the engineers, and designers. “A lot of those guys were in their 60s then. I was just a teenager, but they poured their knowledge into me.”

Dale learned lofting as a part of ship fitting. Back in the day, designers would carve a wooden half model and then cut it in sections and measure each section to get the offsets. “The engineers at Ingalls had a bridge they put over the model and bars that slid back and forth and they used that to get the offsets. It was more accurate.”

While he became skilled in the mathematics and tricks of drawing boats and lofting full size and at tenth scale, Dale also learned how the shipwrights themselves built with molded steel.

“It was kind of barbaric. They had a jig and they’d put the plate on there and put it in the furnace and when it got red hot, they’d pull it out and put this big plate over it. They had these bars that they fit through slots in the plate, and they’d take sledgehammers and bang the steel down onto the jig.”

Most U.S. yards that build commercial fishing vessels avoid designs that require molded steel. When Lars Vinjerud showed Dale the X-type bow he wanted, usually made with molded steel, Dale told him that with a minor modification, they could build it at Williams Fabrication. “Still, we call it the can’t bow because you can’t build it, except here. That’s why we strike it off so well; with Lars, we’re able to set down and be creative.”

Dale had to get particularly creative to get Vinjerud’s new 97-foot lobster boat down to a registered length under 79 feet. “There are standards you have to go by. I had to flatten the keel and then you can come up to 85 percent of the depth of the vessel and measure from there. So, you see how it flares out there,” he says, pointing to the bow. “That’s where they measure from. I had to bring the chines down too, to give it the buoyancy it needed, so we had less room for the propeller and rudder under the stern, but we made it work.”

Noting that Vinjerud initially wanted a wooden deck, Dale points out that with two big live tanks holding 100,000 pounds of lobsters, the boat would be heavy. “I advised against the wooden decks. This boat is very weight sensitive. With those tanks loaded, it’ll only have 36 inches of freeboard — it doesn’t need another 7,000 pounds of wood.”

Having learned his trade before computers existed, Dale does all his design work on a drafting table with a pencil paper. “Lane does all the auto-cad work,” he says but notes that he still has to correct the computer drawings. “The program we use doesn’t fair the lines perfectly. So, we have to go in, remove a frame, spline the line fair, and then put the frame back in.”

But drawing boats involves more than the shape of the hull. “Lane asked me to draw up the piping for the lobster boat, and I did, but then we lost our pipe fitter who’d been with us for 20 years, so he asked me if I could do the work.” Dale didn’t do the welding, but he worked with a new pipe fitter down in the bowels of the lobster boat, setting up the systems for fuel filtration, water separation, and distribution, the lobster tanks, the IMS refrigerated seawater (RSW), and all the other necessaries aboard the vessel.

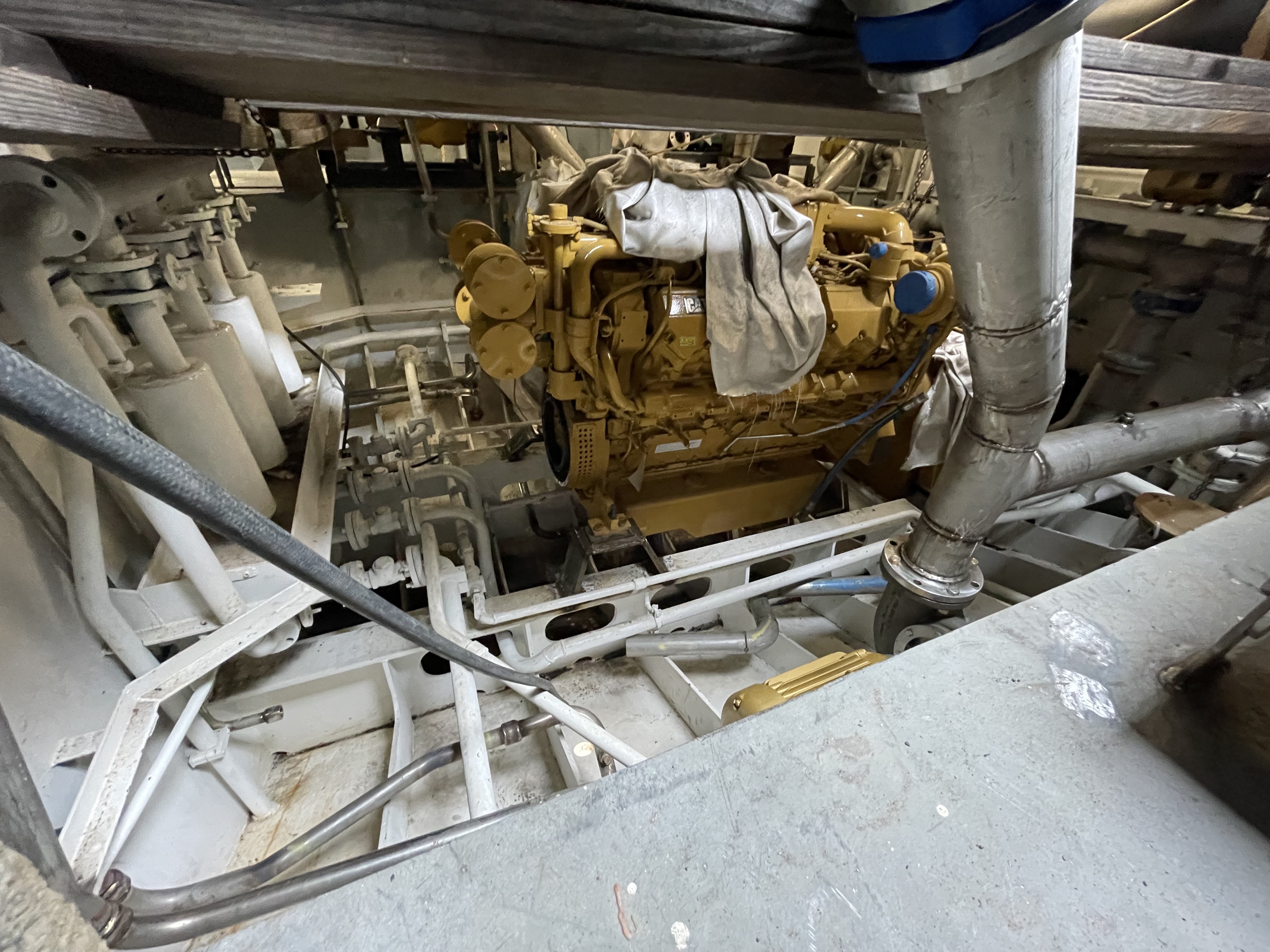

Standing on a catwalk above at the 800-hp Caterpillar main engine, Dale points to all the pipes running around the engine room. “That six-inch that you saw outside on the hull brings water up to the IMS chiller, and then that one there sends it to the starboard tank.” Dale explains how the recirculation system works, complete with various fail-safes in case of problems. “You can run either tank or both on either chiller,” he says.

To keep water out of the fuel, Dale’s system includes four water traps — one for each main fuel tank. “There’s a triple Racor that fuel goes to for the day tank, and the engines use it from there.”

I’m no teenager, but listening to Dale, I could imagine how he felt when those wise oldtimers imparted their knowledge to him. The boatbuilding industry is rife with intergenerational knowledge, tricks learned from grandparents, and old folks teaching the young. While the materials for building commercial fishing vessels have shifted from wood to steel, fiberglass, and aluminum, many of the basics translate across mediums.

“We took some drawing up to Mandeville [Louisiana] to have them do the lofting and make the cut files. I asked them, do you know how to loft? They said they had programs. Well, what they sent us didn’t work, and we lost a lot of money. You have to know how to loft by hand, so you know it’s right.”

Dale’s grandson Preston works in the yard and is learning the trade, but I had to ask: “Dale, why aren’t you someplace teaching this stuff?”

“Well, I would,” he says. “I’d like to.”

Skilled journeymen in the boatbuilding industry remain in demand, and the knowledge that has been passed down, often for hundreds of years, continues in places like Bayou La Batre. Throughout the commercial fishing industry, there is a cry for young people, and in some regions, programs exist to teach the skills needed. This writer, for example, is a graduate of the University of Rhode Island’s Fisheries and Marine Technology Program.

Driving out the gate of the Williams Fabrication yard, I wondered if Dale would find a way to share not just his knowledge but his values with more than one young person at a time. The industry is saying that it needs what he and others like him carry in their heads so that the next generation can “set down and get creative” when it comes to designing boats.