Specialty wooden skiffs continue to provide an essential working platform for some mid-Atlantic inshore fisheries.

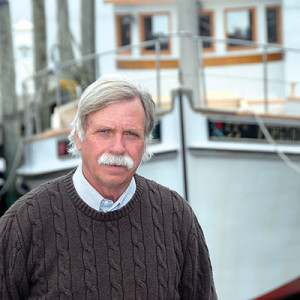

Reedville, Va., wooden boatbuilder George Butler built a 21’ x 8’ pound net seine skiff for pound net fishermen Albert and Stanley Oliff of Warsaw, Va., back in 2001.

The Oliff brothers had purchased fir planks to build the skiff themselves but wisely decided to carry the lumber to Butler and have him build it. When Stanley died in 2015, Albert sold the skiff to fishermen Wayne Fisher and his sons Aaron and Matthew of Leedstown, Va.

They purchased the skiff to work pound nets and gill nets on Rappahannock and Potomac rivers. “We needed a good seine skiff for working our nets, and this boat fit the bill,” says Wayne. “We had worked the boat hard for about six years when a board went bad in the stern.”

When the bottom board in the stern rotted out, Fisher carried the skiff to Richard Holbrook of Colonial Beach, Va., and had a new white oak stern installed. Holbrook specializes in wood and fiberglass boat repair.

“The skiff was originally 21’ but Richard cut the length back to 20’ when he rebuilt and installed the new stern,” says Fisher.

When fishing a pound net, a small wooden outboard-powered flat-bottom skiff is used to move along the sides of a pound net to untie lines and to go inside the net to raise fish trapped in the pocket to the surface.

The fish are positioned in the net pocket so a larger boat can come along the outside of the net. A dip net is mounted to the mast on the larger boat and a power winder operates the dip net.

Fishermen standing inside the wooden skiff guide the dip net down into the fish, and when the net is full, a winder hauls it up and over the gunnels and into the larger boat. The dip net has a release in the bottom that drops fish into the big boat. Three to four men stand and work in the skiff. The skiff is open with no forward top deck cover in the bow because a fisherman must stand as close to the nose of the skiff when fishing the net.

In the spring, the skiff is essential for the layout of the pound net poles in the water, driving poles into the bottom and tying the net to it. “It is the best boat I’ve ever had for laying out nets,” says Fisher.

Butler remembered the boat well because the Oliff Brothers had provided the fir to build the skiff. “I normally use some fir in my skiffs, but they provided enough wood that I could build it mostly out of that type of wood,” said Butler. “It most certainly has good material in it.”

The skiff is powered by a 50 h.p. Yamaha four-stroke outboard engine. "We have three other larger fiberglass boats, but the wooden skiff works better inside of the net than my other boats,” says Fisher. “When the stern went bad, we didn’t think twice about keeping her on the job.”

Butler was the owner of Reedville Marine Railway, where he hauled, maintained, and built boats for over 40 years. He has since sold the railway and officially retired from boatbuilding. He still, however, helps out watermen with repair work on their boats. He also enjoys talking about boats.

“If they continue to use the skiff and keep it maintained, it will last a longtime,” says Butler. “I often wonder where my boats go. It is always good to find out when one is still out there doing the job they were built to do.”