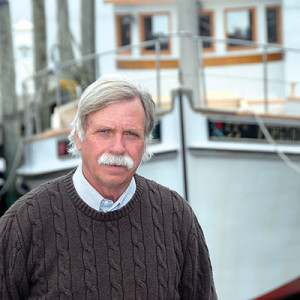

William “Bill” Mullis, owner of B & C Seafood in Newport News, Va., has made a practice of purchasing old vessels and refurbishing each one for the scallop fishery with a hands-on approach. His latest project here at B & C is the Amelia Joyce, a 90’ x 24’ boat slated to rejoin his fleet operating in the Atlantic scallop fishery in Port Judith, R.I.

The interior of the wheelhouse and living quarters are being rebuilt by Nick Rollins, a boatwright of Poquoson, Va., in a small workshop that Mullis built on his property. Rollins, who specializes in fine wooden boat repair, comes from a yacht repair background with Blue Water Yachts in Hampton, Va., where he worked for many years.

The Amelia Joyce was originally built for the Northeast lobster fishery by La Force Shipyard in Bayou La Batre, Ala., known today as Raymond & Associates.

The boat was purchased about two years ago by Mullis from Lars Vinjerud of Ocean Fleet Fisheries in New Bedford, Mass. Mullis had the boat working for one season before bringing it in for the overhaul.

“When I look to purchase an old fishing boat the first thing I look at is who built it” says Mullis. “I’ve bought several old boats built by La Force and all of them were built in the beginning with top grade steel that has held up over time.”

The newly refurbished scalloper brings the number of boats Mullis operates in the fishery to six.

Work on the vessel

Here at the B & C workshop, Rollins has been working full-time since January 2022 on the interior of the boat. The living quarters and pilothouse have been completely gutted and all new wiring and electrical installed.

“It’s like restoring an old car,” says Mullis. “We took everything apart and now we are going to put it back together with all new stuff inside.”

A concrete floor was poured in the living quarters area. Before the concrete was poured, a 12-inch high Line-X coating was installed from the floor up the wall as a barrier between the concrete and steel interior walls.

“Concrete over steel eats steel up faster than anything,” says Mullis. “The Line-X is like what a truck liner is made from and it keeps the concrete from touching the steel.”

The living quarters will include a galley, dining area, captain’s quarters with a full bath and crew quarters with nine berths, including a shower and half-bath.

Rollins is doing all the woodwork in the living quarters and wheelhouse. He has installed 1/2” exterior plywood over the steel walls and 1/2” Medium Density Overlay panels over the plywood. Rollins said the cost of the panels have gone from $50 a sheet to $77 in just a few weeks.

“Nick can do all of the cabinet work, wheelhouse woodwork and all of the woodwork,” says Mullis. “It is more cost effective doing it this way than having a shipyard do the work and it gives Nick steady work. I plan to replace the interior on some of my other boats too.”

“By doing it right here at the plant, I get to know my boats up and down and that is important,” he says. “I don’t have to depend on someone else telling me what I need on my boats. I can see it myself and approach it the way I see it.”