Fishermen in Bristol Bay, Alaska, need to make the most of every hour of their relatively short fishing season. To do so, those in the industry are increasingly turning to the waterjets produced by Hill Innovations.

Providing the tools to enable this kind of productivity kind of support is something the company has been doing since 1985 with introduction of the TRAKTOR JET, the original slow-speed, high thrust waterjet (a combination tailored to the demands of fishing vessels). Since then, the company has developed more than 25 unique waterjet systems. The most recent of these innovations is the Hi Series, which was “designed to make all others obsolete.”

National Fisherman spoke with Len Hill, founder of Hill Innovations, and Len’s son Jason Hill, now president of the company, to better understand why their water jets have become so popular in Bristol Bay. Speaking with NF from Arkansas, where he was born and raised 80 years ago and where his company is now headquartered, Len discussed his experience developing the company’s first waterjets, engineering decisions aimed at getting the best results for fishermen, and much more.

National Fishermen: What difference does your product make for commercial fishermen to improve their productivity and safety?

Jason Hill: In regards to improving productivity for our customer, the HiJets produces more thrust per horsepower in the mid-range speed than the typical high-speed jets. The additional thrust over the high-speed jets allows the HiJet units to get more weight on step. This allows the boat to arrive at the tender ahead of the other slower boats that cannot get on step with heavy loads. Also, the impeller in the Hijet series has four to five times the thickness of high-speed jets, which allows the HiJets to take more abuse to give more reliability to the fisherman in the shallows.

Len Hill: When I started manufacturing the TRAKTOR JET in the mid 1980s, it was a far departure from regular jets. We were twice or three times as big in diameter, and they ended up having a huge nozzle, and so we couldn’t use the same deflector steering apparatus as everybody else used or that Jacuzzi had used on their units. So, I came up with a square nozzle and a clam-shell-type steering.

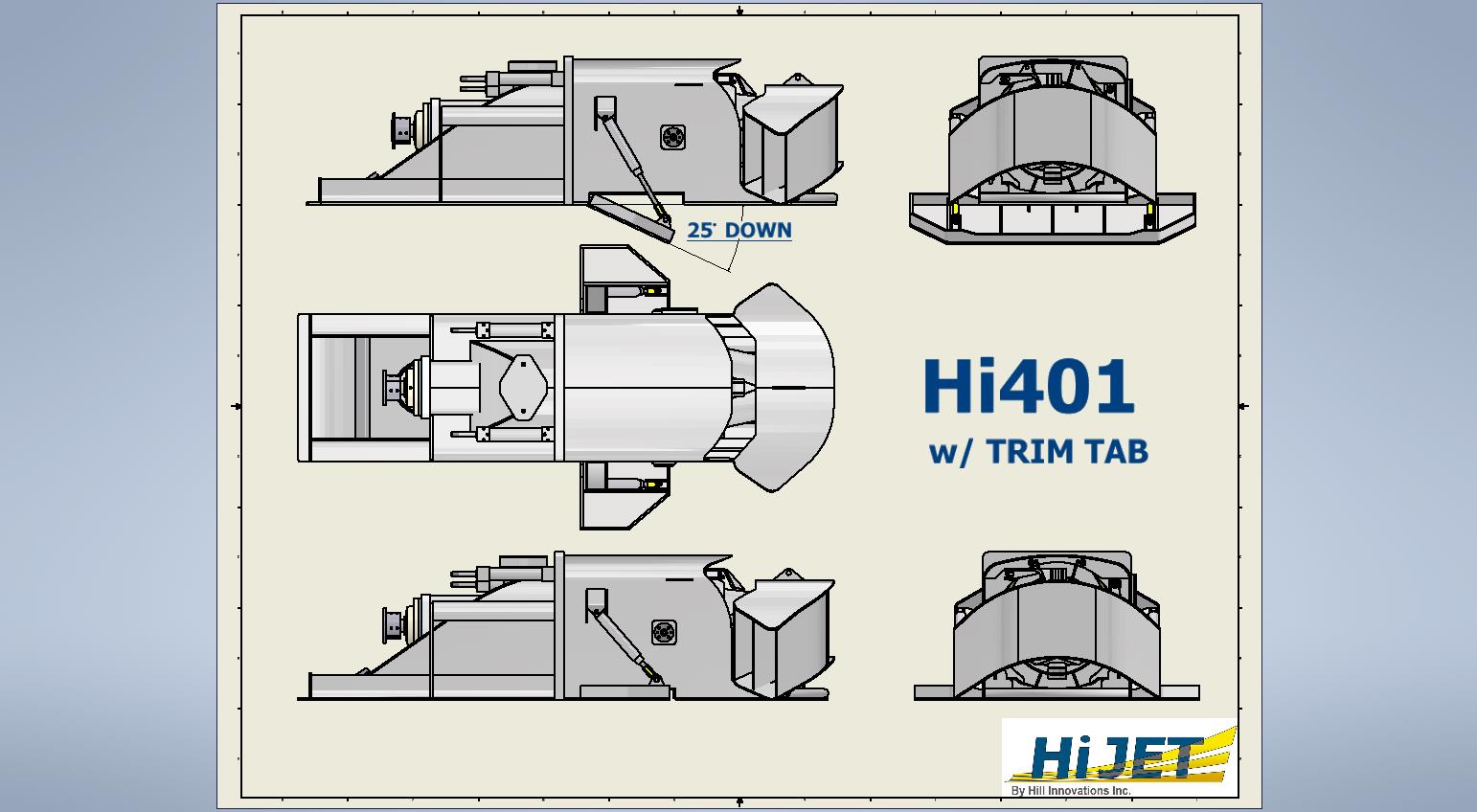

In shallow water you could get rocks or other types of debris in the gates and they would jam up, and we tried all kinds of different things to remedy the problem, we improved it, but we never got it foolproof. Now at Hill Innovation, we got away from the old technology from the TRAKTOR Jet design, and we have gone with a bucket-type reverse system that is virtually impossible to jam.

The new style bucket offers the customer a lot safer unit, plus the HiJets have a jet guard that protects the bucket and steering from impact damage while you are in shallow water bouncing off of rocks and sand bars. The combination of the split-style bucket and the jet guard makes it the safest propulsion system offered in Bristol Bay.

NF: What sort of questions are you most often asked by fishermen about your products?

Jason Hill: Everyone wants to know why the HiJet is a better option than high speeds brand X. The HiJet produces more thrust in the mid-range to get heavier loads on step; it’s more durable due to composite wear ring housing with a stainless steel liner, and a composite stator housing with stainless steel inner assembly (all other jets in the industry utilize cast aluminum stators); and HiJet impellers are four to five times thicker than the competition so our jets can take more abuse longer to keep you fishing longer.

Secondly, they want to know much weight they get on step with our jets. This is a hard question to answer as there are so many variables: the weight of boat, design of hull, center of gravity, etc. So the best answer I can give is we produce more thrust in the speed range to get boats on step, thus we will produce better performance than the competition.

People often ask us what engine we'd recommend for our jets. The reality is the jet does not care, as long as the engine has the horsepower and the gear reduction is correct, there are many great options out there in the marine industry.

And lastly, they want to know what type of controls we recommend. Hill Innovations recommends Glendinning controls if you are wanting to go the electronic controls route, but we do have options to use mechanical inputs for bucket controls.

NF: What has your focus on thrust meant in terms of development and capability?

Len Hill: Hill Innovation’s emphasis on thrust has gone through a paradigm of changes.

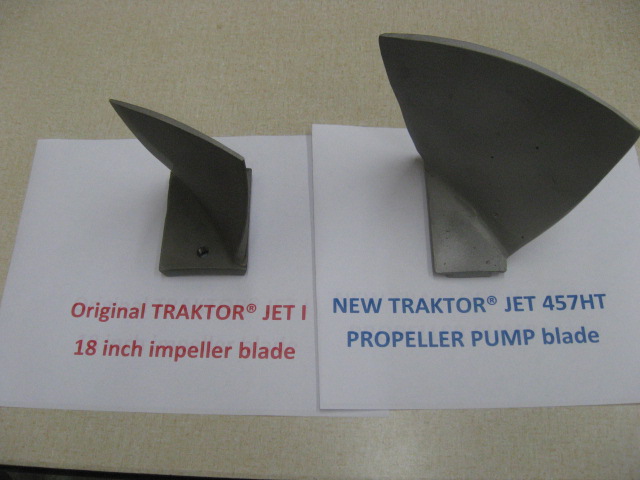

We started out designing waterjets to produce maximum thrust possible at bollard pull because we were making jets starting out to pull gillnets behind skiffs that would do a circle around the fish and come back to the Seiner and pull it in, and the original TRAKTOR JET with only 150 horsepower diesel engine was perfect for this application. We venture into larger jets, and larger boats, and it was not how much bollard pull you had but more how big of a load can you get on a plane and still have a decent cruise and still have the bottom thrust.

So I invented a new type of waterjet that was able to develop a mixed flow impeller that was able to shave off some of the bottom end thrust and gain in middle thrust but not go all the way to being a high-speed jet, because fisherman can’t make any money running around at 40 knots! The best solution for our customers is hauling fish at 18 to 25 knots.

That’s kind of the change we’ve gone through in the last 30 years.

NF: How have you been able to cultivate the sense of trust with your customers that you clearly have?

Len Hill: We do have that, and we’re thankful for it. It’s a byproduct of a Christian family-owned business. I think people can see that we genuinely care about our customers.

Our customers can trust in what we say and that we do what we say, and we genuinely have the customer's livelihood in mind. Hill innovations prides itself in responding to customers’ needs and developing a product that meets their needs.

We also continually improve our products based on our customer's feedback, as we strive to provide the most safe, efficient, and dependable waterjet possible.

NF: What’s the craziest story you’ve heard about how or where your products have made a difference?

Len Hill: There’s not too much funny stuff or crazy stuff that goes on at Bristol Bay boats [laughter].

Some guy, I don’t know why, got caught in the flats with the tide going out, and he was too far in, I guess, and pretty well going aground, not totally, but he used the jet to pump rocks and gravel and sand and a little bit of water mixed with it to actually dredge himself out of there and get into deep enough water where he could float the boat, knowing that he was going to destroy his jet drive in doing that and found out that the thing would still push the boat. He wouldn’t get the performance that he had before, but you know the thing held together and still worked so he was surprised at that and thankful he could use the thing to dredge himself off the flats [laughter].

NF: What advice do you have for any fishermen questioning whether or not they have the thrust and power they really need?

Jason Hill: The fisherman needs to look at what his boat is going to weight out at ready to fish. Lightweight sea trail condition is useless information in reality. The fishermen needs to look at the size of waterjet he is considering and the horsepower going to be used and determine first if he is going to be pushing the cavitation limits of that jet size. If they chose too small diameter jet then they could suffer in performance due to the cavitation breakdown of the thrust of the jet drive.

Best advice, go the next step up in size of jet, a general rule the bigger the diameter of impeller allows for better cavitation resistance the slower the speed range. Also be advised, just because you are adding more power to a smaller pump could make cavitation worst. All high-speed jets have a suggested input horsepower to speed range that they recommend to avoid.

I recommend that a fisherman do his homework, and avoid jets that have very small intakes and very high top-speed capabilities, as this is excellent for fixed-weight patrol boats that want to go 50 knots, but the opposite what is required for a Bristol Bay boat.

Len Hill: They need to look at the loaded boat to unloaded boat time ratio: are you spending a lot of time loaded to get to the tender, and would it be worth it to upgrade to get a boat that would get on plane so you could get to the tender and back quicker to make another set?

NF: How have fishing needs and expectations changed based on newer jets that have more horsepower?

Len Hill: Bristol Bay vessels are getting heavier and wider every year, the expectation of the industry is to get more and more fish on step. Hill Innovations’ newer jets allow the customer to utilize the higher horsepower outputs of present-day marine engines offer. They can carry more fish so they can obtain more weight on plane with properly utilizing the extra horsepower.

Stick on extra horsepower on a smaller jet, you can go faster when you’re empty, but you’re not going to acquire a whole lot more weight on plane because you get into cavitation and that type of thing. With our jets that’s kind of our forte now.

NF: What does it mean in a practical sense for fishermen to be able to carry more fish onboard?

Len Hill: It doesn’t really make sense to make more room to get more fish on board that you can’t do anything with if you can’t get on step. You have got to take that into consideration.

What you’re trying to do goes back to the ratio of getting the boat loaded to getting it unloaded. You have those bigger fish holds, you got to have the equipment to go with it to get the boat on step, so you can get loaded and unloaded and get back to the fishing grounds. The more fish you want to get on step the more thrust you need in the 15 to 20-knot range, and the HiJet is designed to produce the most thrust in this range.

NF: How do your products improve the maintenance and repair logistics that fishermen have to deal with?

Len Hill: We’ve had guys, just like that guy who used [the jet] as a dredge, there’s other guys, they don’t know what happened, but something broke the grate, the grate went through the jet, knocked a couple impeller blades off, wiped out some stator vanes and went on through the jet and they still operated the jet for the rest of the season. So the dependability is a great factor because with that season being so short, man, you’re talking about utilizing every hour.

If the jet is not working, you’re not making money. And as far as I know we’re the only company that has a stash of spare parts stationed during the fishing season in Naknek [Alaska] impellers, thrust bearings, cylinders, tail bearing, and many other parts to support HiJets. Also we have personnel on site in Naknek, and Dillingham in May and June every year to help the fisherman get ready for the season.

NF: What does it mean to fishermen to not lose fishing days on account of boat or gear challenges?

Len Hill: If you don’t break down, you’ve got more money in your pocket. If you don’t break down, you go through the season with nothing happening to your equipment, it’s a big peace of mind to do that and then you’ve got more trust in your equipment going into the next season so you’re not losing sleep over it.

You have confidence in your equipment that its heavy enough to do what it’s supposed to do and you don’t have to worry about that, you just have to worry about where the fish are.

You can shop the entire catalog of Hill Innovations here.