In trawl fisheries, vessels usually spend costly amounts of time and fuel searching for fish. Even with advanced technology, the cost of finding fish comes with the price of investment. To increase efficiency, Kongsberg Maritime of Norway has developed an unmanned surface vehicle that can hunt for fish at a fraction of the cost of a fully manned fishing vessel.

“The vessel is equipped with high-definition SX95 omnidirectional sonar,” says Richard Mills, head of marine robotics sales at Kongsberg. “Then there is a moon pool in which we can put other equipment. We just put an EK80 echosounder in one for a company we can’t name, and we are hoping to demonstrate it next year for NOAA.” According to Mills, the USV can search large expanses of ocean and transmit data to land-based receivers and fishing vessels. “We sit down with our customers and look at cost benefits,” says Mills, noting that the USV could operate for as little as 15 percent of a manned vessel’s crew costs and fuel costs.

The 26.5-foot USV has a 7.3-foot beam and draws 2.3 feet. For receiving commands and transmitting data, the vessel has a mast that reaches 14.4 feet above the sea surface. The vessel can run autonomously or be operated from a laptop PC or radio control with data telemetry via a Kongsberg’s K-MATE control system, with communication through Maritime Broadband Radio and Iridium satellite (VSAT optional).

A 125-hp Steyr Diesel engine can power the vessel at 12 knots, and at that speed is expected to cruise for six to 15 days. But at 4 knots, the USV reportedly can cruise for 20 days.

TASA, the largest fishing company in Peru, has contracted with Kongsberg to put the first USV in operation, and some large U.S. companies are reportedly interested in the new technology. Kongsberg Maritime is developing a whitepaper for the Alaska groundfish fisheries.

In the states, Saildrone Inc., based in Alameda, Calif., has also been working with Kongsberg Maritime, and NOAA, since 2015, developing a sonar-equipped sail-powered USV to conduct climate change and other surveys. This year, with its survey cruises canceled because of the pandemic, NOAA has utilized three saildrones — each equipped with a Simrad EK80 split-beam sounder — for its Bering Sea pollock survey.

According to NOAA, the agency’s scientists believe using acoustic technology on saildrones to survey in the eastern Bering Sea will — based on past comparisons of the technology with ship-based surveys — provide a reliable estimate of pollock abundance. It also helps that pollock are the dominant fish species in this area, minimizing the need to further sample with a trawl net to confirm species identification.

Three 23-foot saildrones, each weighing more than 1,500 pounds, arrived in the Bering Sea in late June and split up to cover most of the U.S. EEZ. Each saildrone will cover a third of the 600-nautical-mile-wide survey area, which is bordered by Alaska’s Aleutian Islands to the south and the edge of the eastern Bering Sea shelf to the west. Cruising at an average speed of 2-3 knots, the saildrones are expected to complete the survey in two months.

According to Jenn Virskus, content manager at Saildrone, no fishing companies have sought to use the company’s USV in active fishing operations, yet. “But the Bering Sea Fisheries Research Foundation did participate in the king crab survey we did last year,” Virskus says.

The Bering Sea Fisheries Research Foundation is an industry-funded organization involved in cooperative research. According to Virskus, the industry organization worked with NOAA and Saildrone Inc. to better understand king crab distribution. In June 2019, researchers tagged 148 mature male crabs while aboard a chartered fishing vessel. Two Saildrone USVs were deployed in October 2019 and again in April 2020 to relocate the tagged crabs.

What’s in the net

While unmanned surface vehicles may aid in fish-finding, other companies are fine-tuning net sensors to make the most of the fish that have been found. Notus Electronics, based in St. John’s, Newfoundland, is improving its trawl sensor systems, Mantis and Echo.

“Our company focuses on trawl sensors,” says Francis Parrott, marketing manager at Notus. “We made a decision to focus on one thing and do it well.”

According to Parrott, Notus’ Mantis and Echo systems are providing fishermen with information needed to increase efficiency. The Mantis system includes sensors on the net that monitor the position of the net and the catch, and a paravane receiver that collects the signals and sends them on to the wheelhouse for processing. The paravane can be set over the side or towed.

“It’s like a wing with a hydrophone. You can think of it as an antenna, and the sensors as transmitters,” Parrott says. The sensors monitor the spread of the doors, the position of the headrope and sweep in relation to the bottom, and the quantity of fish going into the net.

“That’s important for redfish, because the quantities can be huge and you can damage the gear,” Parrott says, adding that the system isn’t just one-way. “We are the only manufacturers of an active system,” he says. “It’s a two-way system. If a captain wants data on trawl wire length every 5 seconds, he flips a switch and sends a signal to the sensors mounted on the doors. Then those sensors send a signal back to the receiver on the paravane. It’s all wireless.”

Parrott notes that many of the boats using the Mantis system are factory trawlers that only get hauled out about every five years. Besides providing a clearer signal, having a receiver separate from the hull enables regular maintenance.

In addition to doing its own manufacturing, and research and development, Notus works with Newfoundland’s Memorial University and often models its various systems’ performance in the Memorial’s tow, flume, wave and ice test tanks. Ice can be a problem for boats fishing the rich waters close to the Arctic.“Of course, vessels operating in ice have to have the receiver mounted on the hull,” Parrott says.

Notus is also logging success with its Echo system for shrimp fishermen. “That’s wildly popular,” Parrott says. “You can’t see shrimp on a sounder because they have no bladder, what echo does is pick up the sound of shrimp hitting the grid, so captains can know where they’re getting shrimp and focus on that sweet spot. The guys who don’t have this can’t keep up with the ones who do.”

Capt. Réjean Côté, of the F/V Helen M. Cadegan, says that using Echo “is the first time in 43 years of shrimping that I know exactly where I have been catching the shrimp.”

The Icelandic company Marport is also in the net sensor business, and the company’s U.S. branch is focused on Alaska’s groundfish trawlers.

“Right now we are fine-tuning our sensors for twin- and even triple-trawl systems,” says Patrick Belen, sales manager for Marport USA. According to Belen, the Marport sensors can export data directly into Olex, TimeZero and other bottom building programs in real time. “We can provide a 3-D presentation that is reality based, enabling the captain to maneuver around obstacles.”

The big developments with Marport’s sensors are around production and multiple net systems.

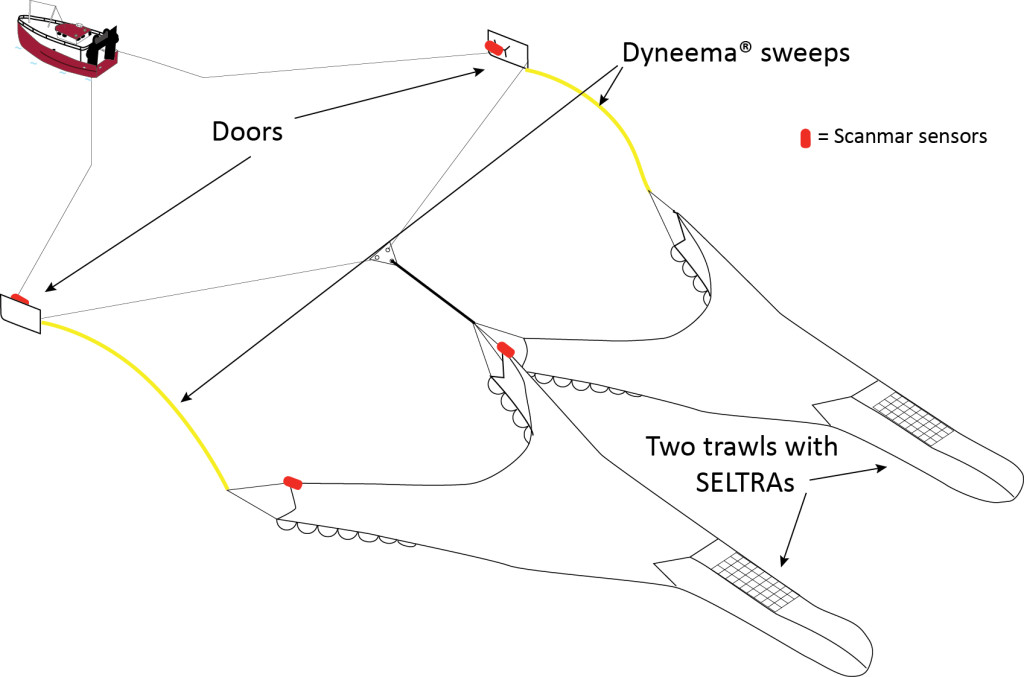

“The quota is not going to change,” says Belen. “What is going to change is efficiency.” To that end he points out that in the last 2 1/2 years, many big boats have started using twin trawls, where two nets are towed between two doors. “In the middle, where the nets connect, they put a clump weight and another wire to the boat. They can almost double the spread of the doors,” he says. Belen notes that boats using multinet systems are towing less net through the water and often getting more fish.

Belen explains that the usual configuration for sensors includes one on each door, one on the clump weight, one on each headrope and one near the cod end. “That’s six, but captains may want to add more catch sensors. They may add as many as three additional sensors.” The sensors collect a variety of data, Belen notes, including trawl symmetry and speed of water moving through the net. “They want to know that the net is deployed according to the design,” he says.

While Marport and other companies — such as multiple net system designer Dantrawl — work closely with fishermen, covid-19 has taken a toll on the ability of equipment manufacturers to get on board boats.

“We can’t send our people to Dutch Harbor right now,” says Belen. “We are collecting data remotely, but it’s not the same as being right there. It’s surprising how much you can learn from these guys. They know what they’re seeing, and they know what they want.”